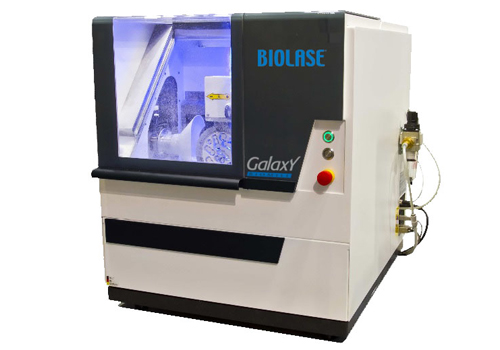

دستگاه میلینگ

The CORiTEC 140i machine system is perfectly suited for everyday use and for grinding of virtually all block materials available on the market. The machine can directly produce restorations when used in combination with an intra-oral scanner. Also, the system is often used as specialized equipment in labs and milling centers for special wet processing of a wide variety of block materials. The sturdy industrial design of the machine makes processing with highest-quality output possible, even the production of premilled abutments

Number of axes and machining type: 4-axis simultaneous machining

Max. setting angle of the rotary axis: 360° processing possible

Wet processing: Integrated

Maximum speed / Pmax: 60,000 rpm / 0.4 kW

Axle drives: Microstep motors

Tool fitting: 3 mm shaft

Tool changer: 6-fold

Workpiece changer: Manual /1-way and 3-way adapter possible/block processing

Weight: 55 kg

Width x depth x height: 470x575x405 mm

Supply voltage / frequency / power 100V-240 V/50/60 Hz/800 W

Compressed air supply 6-9 bar constant supply, 50 liters/minute

4axis processing

integrated TouchScreen operation

processing of all commonly used material blocks and premilled abutments

multi-adapter with up to three blocks

automatic 6-fold tool changer with Tool Management

tool runtime control/breakage control

highest precision through high-frequency spindle with up to 60,000 rpm

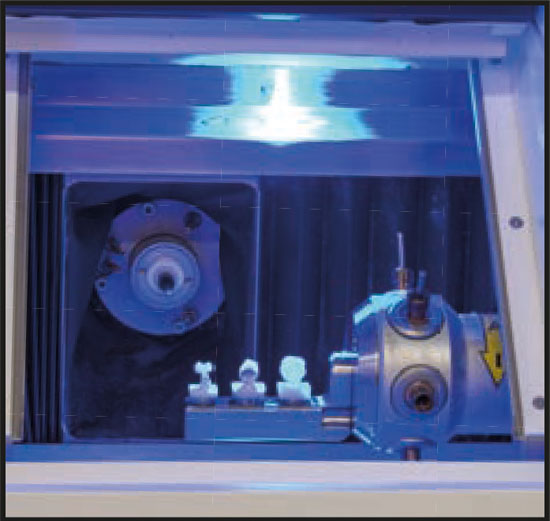

fully integrated wet machining with filter system

Materials: Premilled abutments, zirconium dioxide, aluminum oxide, PMMA, plastics, composites, wax, glass ceramic, hybrid ceramics

Compatibility: CAD/CAM blocks (1-fold and 3-fold adapter), nt-trading pre-milled abutments, Medentika PreFace® abutments

آدرس: تهران، میرداماد، خیابان شمس تبریزی شمالی، کوچه نیک رای، پلاک 3، طبقه سوم، واحد 6

تلفن:021-75381

فکس:

021-22250220

ایمیل: info@nisham-aryana.com